INDUSTRIAL

AUTOMATION

HOME / SERVICES / INDUSTRIAL AUTOMATION SYSTEMS

Cyth Systems

INDUSTRIAL AUTOMATION SYSTEMS

Industrial automation involves integrating Data Acquisition and control logic with various third-party components, devices, and sensors. Bringing together this broad mix of technologies, and integrating them into a final solution requires Mechanical, Electrical, and Software Engineers, and a common technology platform to ensure all system components work cohesively.

Leveraging the LabVIEW, PXI, and CompactRIO, platforms we can solve extremely complex industrial automation challenges and deliver success for our customers that could not otherwise be achieved.

Industrial Automation CATEGORIES

Automated Assembly

We are often given a challenge to help automate the assembly of a product, or to provide assistance to a technician to improve or control assembly.

Typically we integrate equipment to apply pressure, torque, or to automate cutting, gluing, or grinding. WIth the help of our measurement and control automation platforms, we provide the control signals and measurement feedback to automate product assembly.

Part Handling

Laser or Ultrasonic Welding

Pressing or positioning of parts

Product Treatment & Handling

Much of manufacturing requires highly repetitive movements. By automating manufacturing processes such as the treatment of a product, material, or parts we can ensure that your manufacturing processes are optimized for quality and throughput.

Cutting or trimming

Spraying or Dispensing

Polishing and Grinding

Verification and Measurement

Measurement and verification of mechanical component during and after automated assembly or treatment helps to ensure the proper positioning, dimensions, or angles of manufactured parts.

Our team can help you define and select the appropriate measurements, data, images, or guide users throught the process of verifying a product is manufactured properly.

Measurement and Sensor Data Collection

Weighing, Dimensioning

Vision Inspection, Defect detection

Counting & Classifying

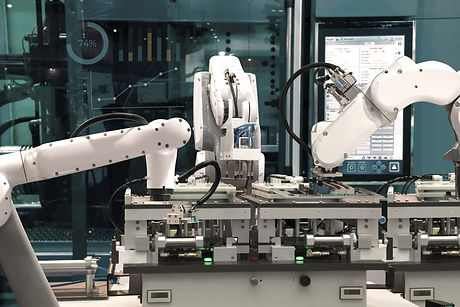

Motion and Robotics

Much of the work of automation is making things move. We need to make fast movements, precision movements, intelligent movements, or grip and manipulate parts like a human hand.

Steppers, Servos

Rotary or Linear motion

6-Axis Robots or SCARA

Pneumatics and Grippers

"I came to Cyth with a unique automation request, and while it was new to them it was very similar to other things they had automated."

-R.R., Healthcare Product Design Manager

Integrating third-party TECHNOLOGY

for Industrial Automation

We build Automated Industrial solutions around a platform including LabVIEW, CompactRIO, and countless other third-party products and components integrated together.

These tools provide a powerful and flexible foundation for us to create custom solutions for just about any automation task. Learn more about our technology.

Steppers, motors, servos, pumps, valves, relays, lasers, sensors.... and much, much more.

.png)

%20(1).png)

A time-tested PROCESS

for Industrial Automation

Over the years, we have developed a fine-tuned process that helps ensure the success of Automated Test projects.

Even with the challenges and discoveries that are common with automation projects, our processes promote better requirements gathering, flexible budgeting, detailed communication, and milestone tracking.

Discovery phase (explore needs)

Prototyping

Design review

Functional demo

Factory acceptance test

Cyth acceptance test

The right TEAM for

Automated Test & Measurement

The experience and knowledge of the engineering team working on your project is a key component of project success.

Our engineers have a broad range of experience and training, and mentoring on projects that span multiple industries and disciplines.

As a team we are experts at creating solutions that incorporate a broad range of instruments, sensors and components product test and quality processes, benchtop instruments, databases, reports, and so much more.

%20(1).png)

"Working with Cyth Systems is refreshing. Status Reports, Budget updates, design meetings... the way projects should be done"

-R.J., Senior Quality Engineer

INDUSTRIAL AUTOMATION

Project PORTFOLIO

Cyth Systems has successfully developed numerous of Industrial Automation projects across every industry. The projects below are very diverse, but they share many common characteristics, and all combine together in our shared experience, history, and processes.

"Every project is unique, but all projects share many common features. No matter what your project requirements are, we know how to get you there."

We're Trusted by