High-Precision Calibration and Prover System for Natural Gas Meters

- markvasat

- Oct 7, 2022

- 4 min read

Updated: Oct 18, 2023

The Challenge

A manufacturer of industrial gas meters approached us with the need for a system to control and automate the measurement of their end-of-line gas meter prover.

The Solution

Using NI CompactRIO we built the customer a two-part system for the control and automated test of their natural gas meter prover that improved their quality control process and validated product accuracy.

The Story//The Cyth Process

A prover is a piece of equipment that calibrates and verifies a fiscal or change of custody gas flow measurement device’s accuracy. In the case of a natural gas meter, verifying the product’s accuracy before deployment is vital. This is because meters give a reading of a customer’s usage (of a product like natural gas) and they are therefore charged accordingly. Accuracy in this process is a requirement as both customers and providers depend on it.

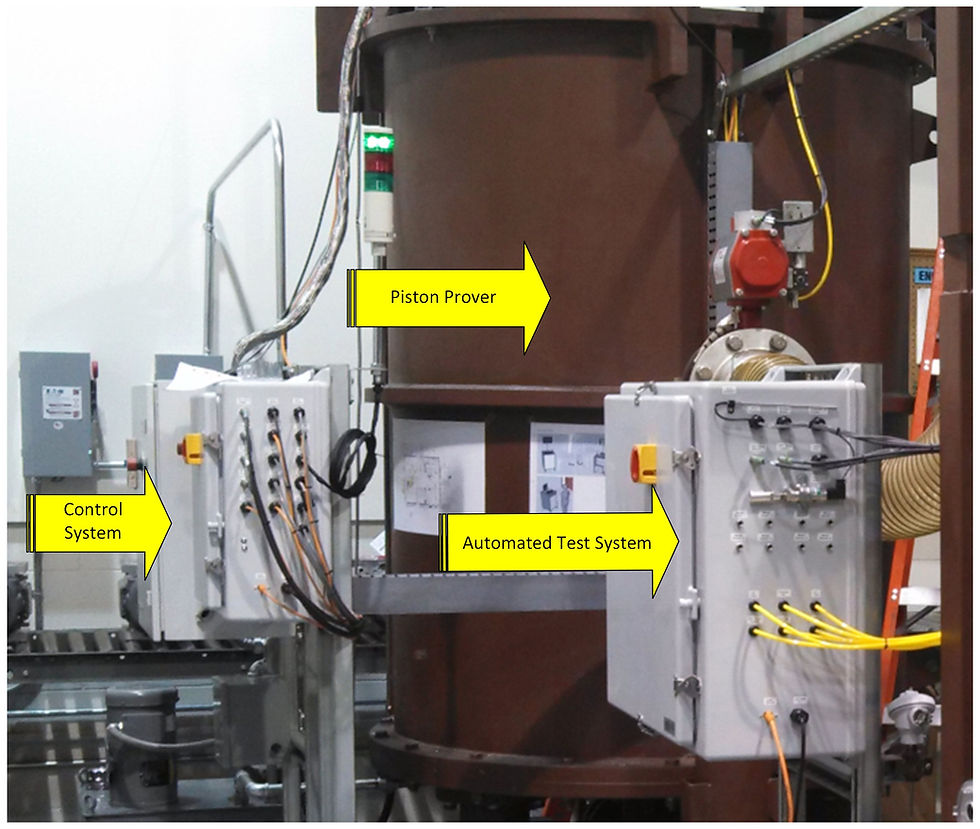

A manufacturer of industrial natural gas meters approached us with the need for a system to control and automate the test of their piston prover. Their current piston prover was a piece of high-accuracy analog machinery that needed upgrading to incorporate electronic controls. To run the piston and be able to test their product required two separate subsystems. One would control the mechanics, and the other was an automated test for taking and tracking measurements. These two separate systems needed the ability to communicate and coordinate the prover’s entire test process.

Figure 1. The piston prover’s two separate systems: control and automated test.

The main physical component of the piston prover was a cylindrical drum body, with a 6 ft diameter and 20 ft height. Inside the drum was a piston responsible for pushing air out of the drum’s body and into the meter via an outflow valve and pipe. This piston needed to be precisely controlled to be able to calculate the amount of air pushed vs. the meter’s reading with an accuracy that met the standards set by the US Units and Measures boards. Based on the percentage difference between the calculated and measured values, the meters were rated as ready for market or not. Repeatability and accuracy were critical as each meter must be audited yearly for its functional accuracy.

To address the accuracy and repeatability needs of this project, our engineering team began building the piston prover’s control system using the NI CompactRIO platform. The NI cRIO provided a chassis to which we added modules supporting the I/O precision and flexibility we needed. Another benefit the CompactRIO platform offered was the ability to program our real-time, closed-loop control application using LabVIEW Real-Time and FPGA modules. The CompactRIO’s platform allowed us to communicate with various sensors at over 25 ns on a 40 MegaHz clock which was critical for the system’s safety relay requirements. The cRIO’s ability to handle over 80+ inputs and outputs (including flow, valve control, temperature, pressure, and humidity sensor readings) made it perfectly suited to meet our project requirements while greatly reducing the time necessary to design and engineer the solution.

Figure 2. The piston prover control systems during installation.

Our team programmed the control system’s hardware to control the acceleration and deceleration of the prover’s piston. This was done using a custom closed-loop PID algorithm, which continually monitored the piston’s speed and pressure feedback for continuous speed adjustments. This was critical for testing since the meter was tested at three different flow rates, which were determined by the piston head’s acceleration and speed. As well, to provide volumetric accuracy during testing the prover’s piston head had to be programmed and calibrated for accurate position control. This calibration was set using metrology standard gauge blocks which could be detected by the piston as it moved using a laser. To add, our team installed a linear encoder which ensured a nanometer precision of the prover’s piston head.

At Cyth we consider operational safety to be a critical component to consider for any high-speed or high-pressure control system. Since the prover’s output could reach over 200 PSI, our development team created a safety control loop that would instantly take over control of the system if any unsafe conditions were identified. An emergency stop sequence that included a pressure release valve and a hard stop for the motor driving the piston was also implemented so an operator could immediately halt the test in case of an emergency.

Overcoming the Obstacles

The largest obstacle our team faced was creating the prover’s control and automated measurement systems without in-person access to the customer’s equipment. The customer’s equipment was located in Texas and the size of the prover and its parts made the cost prohibitive to ship it to our engineering team in San Diego. This meant that all development had to be done remotely without physical access to the prover hardware.

To solve this issue, our team developed a hardware in the loop model (HIL) that ran on NI CompactRIO to test the prover’s piston controls and provided a means to manually test the piston’s other sensors through physical actuation of the transducers. Both the control system and automated test system were preassembled in San Diego and prepared so that upon arrival we could install them within time constraints.

Delivering the Outcome

Our engineering team designed and deployed a two-part system for the control and automated test of our client’s natural gas meters. Our systems were able to provide the customer with an automated solution that improved their quality control process and validated their product accuracy. Using the NI CompactRIO hardware platform our team was able to meet the high-speed communication needs of the prover’s control system as well as handle 80+ sensor inputs and outputs. Critical to the system’s development was our ability to program the piston prover’s closed-loop PID algorithm and safety feedback loops using LabVIEW. Our two-part system achieved the nanometer precision accuracy required by the piston prover’s air delivery. Since deployment, our system has been running consistently and helping our customer validate their industrial natural gas meters for both consumers and providers alike.

Figure 3. Piston prover control system.

Figure 4. Automated measurement system for 80+ sensor inputs and outputs.

Technical Specifications

Control System

1 x NI CompactRIO with Add-on Modules:

1 x Anal Piston P\Control system. system.system.ystem.stem.tem.em.m.sm.

1 x Analog Out 4-20mA

1 x Analog Input 0-10V

1 x Analog Ouput 0 -10V

1 x Industrial Digital Input

1 x Industrial Digital Output

1 x Modbus

1 x Ethernet IP

Automated Test System

1 x NI CompactRIO with Add-on Modules:

1 x Analog Input

1 x Digital Input

1 x 4-20 mA Current (flow, temperature, pressure, and humidity sensors)

1 x 24V Industrial Digital Input

1 x 24V Industrial Digital Output (open and close valves)

Comments